Misc

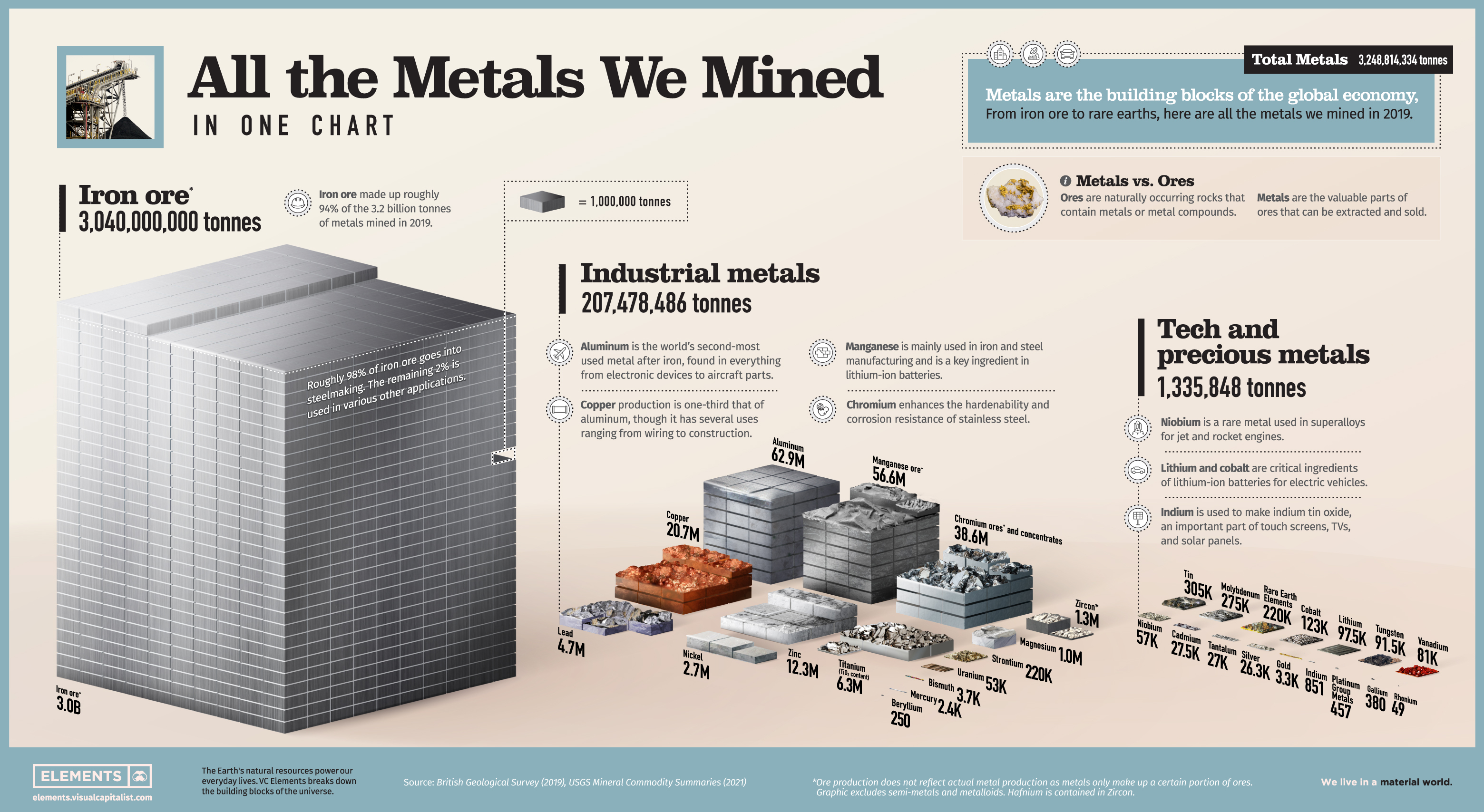

All the Metals We Mined in One Visualization

All the Metals We Mined in One Visualization

Metals are all around us, from our phones and cars to our homes and office buildings.

While we often overlook the presence of these raw materials, they are an essential part of the modern economy. But obtaining these materials can be a complex process that involves mining, refining, and then converting them into usable forms.

So, how much metal gets mined in a year?

Metals vs Ores

Before digging into the numbers, it’s important that we distinguish between ores and metals.

Ores are naturally occurring rocks that contain metals and metal compounds. Metals are the valuable parts of ores that can be extracted by separating and removing the waste rock. As a result, ore production is typically much higher than the actual metal content of the ore. For example, miners produced 347 million tonnes of bauxite ore in 2019, but the actual aluminum metal content extracted from that was only 62.9 million tonnes.

Here are all the metals and metal ores mined in 2019, according to the British Geological Survey:

| Metal/Ore | Quantity Mined (tonnes) | % of Total |

|---|---|---|

| Iron Ore | 3,040,000,000 | 93.57% |

| Industrial Metals | 207,478,486 | 6.39% |

| Technology and Precious Metals | 1,335,848 | 0.04% |

| Total | 3,248,814,334 | 100% |

Miners produced roughly three billion tonnes of iron ore in 2019, representing close to 94% of all mined metals. The primary use of all this iron is to make steel. In fact, 98% of iron ore goes into steelmaking, with the rest fulfilling various other applications.

Industrial and technology metals made up the other 6% of all mined metals in 2019. How do they break down?

Industrial Metals

From construction and agriculture to manufacturing and transportation, virtually every industry harnesses the properties of metals in different ways.

Here are the industrial metals we mined in 2019.

| Metal | Quantity Mined (tonnes) | % of Total |

|---|---|---|

| Aluminum | 62,900,000 | 30% |

| Manganese Ore | 56,600,000 | 27% |

| Chromium Ores and Concentrates | 38,600,000 | 19% |

| Copper | 20,700,000 | 10% |

| Zinc | 12,300,000 | 6% |

| Titanium (Titanium Dioxide Content) | 6,300,000 | 3% |

| Lead | 4,700,000 | 2% |

| Nickel | 2,702,000 | 1% |

| Zirconium Minerals (Zircon) | 1,337,000 | 1% |

| Magnesium | 1,059,736 | 1% |

| Strontium | 220,000 | 0.11% |

| Uranium | 53,400 | 0.03% |

| Bismuth | 3,700 | 0.002% |

| Mercury | 2,400 | 0.001% |

| Beryllium | 250 | 0.0001% |

| Total | 207,478,486 | 100% |

Percentages may not add up to 100 due to rounding.

It’s no surprise that aluminum is the most-produced industrial metal. The lightweight metal is one of the most commonly used materials in the world, with uses ranging from making foils and beer kegs to buildings and aircraft parts.

Manganese and chromium rank second and third respectively in terms of metal mined, and are important ingredients in steelmaking. Manganese helps convert iron ore into steel, and chromium hardens and toughens steel. Furthermore, manganese is a critical ingredient of lithium-manganese-cobalt-oxide (NMC) batteries for electric vehicles.

Although copper production is around one-third that of aluminum, copper has a key role in making modern life possible. The red metal is found in virtually every wire, motor, and electrical appliance in our homes and offices. It’s also critical for various renewable energy technologies and electric vehicles.

Technology and Precious Metals

Technology is only as good as the materials that make it.

Technology metals can be classified as relatively rare metals commonly used in technology and devices. While miners produce some tech and precious metals in large quantities, others are relatively scarce.

| Metal | Quantity Mined in 2019 (tonnes) | % of Total |

|---|---|---|

| Tin | 305,000 | 23% |

| Molybdenum | 275,000 | 21% |

| Rare Earth Elements | 220,000 | 16% |

| Cobalt | 123,000 | 9% |

| Lithium | 97,500 | 7% |

| Tungsten | 91,500 | 7% |

| Vanadium | 81,000 | 6% |

| Niobium | 57,000 | 4% |

| Cadmium | 27,500 | 2% |

| Tantalum | 27,000 | 2% |

| Silver | 26,261 | 2% |

| Gold | 3,350 | 0.3% |

| Indium | 851 | 0.06% |

| Platinum Group Metals | 457 | 0.03% |

| Gallium | 380 | 0.03% |

| Rhenium | 49 | 0.004% |

| Total | 1,335,848 | 100.00% |

Percentages may not add up to 100 due to rounding.

Tin was the most-mined tech metal in 2019, and according to the International Tin Association, nearly half of it went into soldering.

It’s also interesting to see the prevalence of battery and energy metals. Lithium, cobalt, vanadium, and molybdenum are all critical for various energy technologies, including lithium-ion batteries, wind farms, and energy storage technologies. Additionally, miners also extracted 220,000 tonnes of rare earth elements, of which 60% came from China.

Given their rarity, it’s not surprising that gold, silver, and platinum group metals (PGMs) were the least-mined materials in this category. Collectively, these metals represent just 2.3% of the tech and precious metals mined in 2019.

A Material World

Although humans mine and use massive quantities of metals every year, it’s important to put these figures into perspective.

According to Circle Economy, the world consumes 100.6 billion tonnes of materials annually. Of this total, 3.2 billion tonnes of metals produced in 2019 would account for just 3% of our overall material consumption. In fact, the world’s annual production of cement alone is around 4.1 billion tonnes, dwarfing total metal production.

The world’s appetite for materials is growing with its population. As resource-intensive megatrends such as urbanization and electrification pick up the pace, our material pie will only get larger.

Misc

Visualizing Global Aluminum Production

China dominates global production with nearly 60% share.

Visualizing Global Aluminum Production

This was originally posted on our Voronoi app. Download the app for free on iOS or Android and discover incredible data-driven charts from a variety of trusted sources.

This infographic shows estimated aluminum smelter production by country in 2023, based on data from the most recent U.S. Geological Survey (USGS) Mineral Commodity Summaries, published in January 2024 .

From this data, we can see that China leads as the top producer, accounting for nearly 60% of the world’s smelter capacity. Its neighbor India is the second-largest producer, making only a tenth of China’s output.

| Country | 2023 Aluminum Smelter Production (tonnes) | % of total |

|---|---|---|

| 🇨🇳 China | 41,000,000 | 59% |

| 🇮🇳 India | 4,100,000 | 6% |

| 🇷🇺 Russia | 3,800,000 | 5% |

| 🇨🇦 Canada | 3,000,000 | 4% |

| 🇦🇪 United Arab Emirates | 2,700,000 | 4% |

| 🇧🇭 Bahrain | 1,600,000 | 2% |

| 🇦🇺 Australia | 1,500,000 | 2% |

| 🇳🇴 Norway | 1,300,000 | 2% |

| 🇧🇷 Brazil | 1,100,000 | 2% |

| 🌍 Rest of the World | 9,460,000 | 14% |

| Total | 69,560,000 | 100% |

Responsible for 5% of global aluminum output, Russia has been targeted by recent sanctions from the U.S. and the UK.

The sanctions include prohibiting metal-trading exchanges from accepting new aluminum produced by Russia and barring the import of the Russian metal into the U.S. and Britain. The actions are aimed at disrupting Russian export revenue amid Moscow’s ongoing invasion of Ukraine.

The World’s Most Common Metal

Aluminum is the primary material used for making cans, foil, and many other products. It originates from bauxites, rocks composed of aluminum oxides, and various minerals.

Approximately 25% of annually produced aluminum is utilized by the construction industry, while another 23% is allocated to vehicle frames, wires, wheels, and other components within the transportation sector. Aluminum foil, cans, and packaging constitute another significant end-use category, accounting for 17% of consumption.

Despite its extensive use, aluminum is still plentiful. Aluminum is the world’s most common metal by crustal abundance, making up 8.2% of the Earth’s crust.

According to the USGS, global resources of bauxite are estimated to be between 55 billion and 75 billion tonnes and are sufficient to meet world demand for metal well into the future.

Misc

Brass Rods: The Sustainable Choice

Brass rods can help cut emissions in machine shops, be recycled without losing properties, and contribute to a cleaner environment.

Brass Rods: The Sustainable Choice

Brass rods have a powerful lineup of green attributes, making them the sustainable choice for manufacturers and end-users of precision machined and forged parts.

This infographic, from the Copper Development Association, shows how brass rods can reduce emissions in machine shops, be recycled without losing properties, and contribute to a cleaner environment.

The Brass Rod Circular Economy

The metallurgical properties of brass allow pre- and post-consumer sources of brass scrap to be recycled with no loss in properties.

Brass scrap can retain over 90% of the original material value. In addition, brass doesn’t need energy-intensive processing, unlike steel and aluminum, which must be smelted and refined before being recycled into new products.

As a result, there is a greater chance that steel and aluminum scrap will end up in landfills.

Most brass-rod alloys produced in North America contain 95% or higher recycled content.

Closed-loop recycling of brass keeps this valuable engineering material out of landfills, reducing the need for new mines and all the environmental impacts that entails.

Higher Machinability Leads to Lower Operational Carbon Emissions

Machinability is how easily a material can be worked using cutting processes. It directly impacts the amount of energy required to produce finished parts.

With typical machine shops producing millions of parts each year, the carbon impact can be significant.

Here’s how brass and steel compare when manufacturing complex parts using computer numerical control (CNC) machining.

| Material | Brass | Steel |

|---|---|---|

| Type | Free-cutting brass (C36000) | Free-cutting steel (12L14) |

| Maximum machinability rating (0-100) | 100 | 21 |

| Metal Removal Rate (cubic inches per minute) | 0.238 | 0.114 |

| Time to remove material (hours) | 161,111 | 336,111 |

| Energy required to produce parts (kilowatt-hour) | 9,475 | 18,931 |

In this example, using brass represented a savings of 3,510 kg in carbon dioxide (CO2).

The significantly longer tool life enabled by brass also reduces the need for new cutting tools, further decreasing emissions.

High recycled content and exceptional machinability make brass rods the sustainable choice for manufacturers and end-users seeking to reduce their environmental footprint and support the transition to a low-carbon future.

Explore the advantages of brass rod solutions.

-

Electrification3 years ago

Electrification3 years agoRanked: The Top 10 EV Battery Manufacturers

-

Electrification2 years ago

Electrification2 years agoThe Key Minerals in an EV Battery

-

Real Assets3 years ago

Real Assets3 years agoThe World’s Top 10 Gold Mining Companies

-

Electrification2 years ago

Electrification2 years agoMapped: Solar Power by Country in 2021

-

Energy Shift2 years ago

Energy Shift2 years agoWhat Are the Five Major Types of Renewable Energy?

-

Electrification2 years ago

Electrification2 years agoThe World’s Largest Nickel Mining Companies

-

Misc3 years ago

Misc3 years agoThe Largest Copper Mines in the World by Capacity

-

Energy Shift2 years ago

Energy Shift2 years agoThe Solar Power Duck Curve Explained