Misc

How Metals Prices Performed in 2021

![]()

How Metals Prices Performed in 2021

Looking back on what gave investors strong returns in 2021, it was the year of industrial and energy metals.

As demand for industrial goods surged, so too did their material metals. But unlike energy prices which rose across the board last year, not all metals managed positive returns.

This infographic looks at the year-over-year return on metals prices from January 1 to December 31 of 2021, using pricing data tracked by Tradingeconomics.com.

Inflation and Raw Material Demand Spur Industrial Metals

Last year saw inflation hit 30-year highs as the world’s reopening resulted in unprecedented demand for base and energy metals.

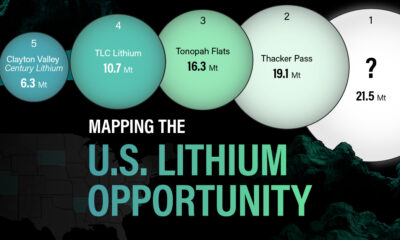

Essential materials for electric vehicle (EV) battery production like lithium and cobalt were among the top performers as EV sales continued to grow in 2021.

| Metal | Annual Return in 2021 |

|---|---|

| Lithium | 496.7% |

| Magnesium | 207.6% |

| Cobalt | 115.2% |

| Tin | 93.6% |

| Molybdenum | 90.4% |

| Neodynium | 78.3% |

| Aluminum | 38.3% |

| Indium | 32.3% |

| Germanium | 31.7% |

| Gallium | 31.6% |

| Nickel | 29.4% |

| Zinc | 28.1% |

| Copper | 26.8% |

| Lead | 14.8% |

| Steel | 7.7% |

| Manganese | 7.2% |

| Gold | -3.5% |

| Platinum | -10.4% |

| Silver | -11.5% |

| Rhodium | -20.5% |

| Palladium | -22.0% |

| Iron ore | -24.0% |

Source: Tradingeconomics.com

Magnesium was another top performer last year, as skyrocketing coal prices impacted the metal, which uses coal as part of the feedstock in the smelting process. In addition, concerns over production suspensions in China for environmental reasons spurred magnesium prices further amidst potential shortage fears.

Iron ore was the only base metal with negative returns, with demand largely curbed by China’s slowing growth and pledge to reduce steel output in May of last year.

Lithium and Other EV Metals Outperform

Last year saw major automakers like Ford and GM commit themselves to all new car sales being zero emission by 2040, spurring an 80% rise in electric vehicle sales in 2021.

As a result, essential battery metals like lithium, cobalt, lead, and nickel were all in high demand as automakers secured these essential materials for their battery production.

The start of 2022 has also seen more positive catalysts for nickel specifically, as Tesla secured a supply deal with Talon Metals for 75,000 tonnes of nickel concentrate over six years.

PGM Prices Falter

Palladium and platinum had strong starts in the first half of the year as well, but chip shortages resulted in a slowdown in automotive production and a drop in demand for the two metals.

Both of these key platinum group metals (PGMs) finished 2021 with double-digit drawdowns, with platinum returning -10.4% and palladium returning -22.0%.

Metals analysts are mixed on whether the two metals (primarily used in automotive catalytic converters) will see a recovery in demand, which would be led by easing chip shortages and supply chain issues.

Gold and Silver Struggle to Hold Value

As the world focused on securing the necessary raw materials for the clean energy transition, gold and silver lagged behind.

Although both precious metals wavered as stores of value, returning -3.5% and -11.5% respectively, bullion sales from the U.S. mint rose by 48.4% compared to 2020.

Despite gold’s underwhelming performance while equities, cryptocurrencies, and other commodities surged, upcoming forecasted rate hikes have historically spurred reversals for the precious metal.

As 2022 has started with equity prices slumping, a potential flight to the safety of hard assets and the continuous demand for raw materials needed for the clean energy transition could set up a positive 2022 for metals.

Misc

Brass Rods: The Secure Choice

This graphic shows why brass rods are the secure choice for precision-machined and forged parts.

Brass Rods: The Secure Choice

The unique combination of machinability and recyclability makes brass rods the secure choice for manufacturers seeking future-proof raw material solutions.

This infographic, from the Copper Development Association, shows three ways brass rods give manufacturers greater control and a license to grow in the competitive market for precision-machined and forged products.

Future-Proof Investments in New Machine Tools

A material’s machinability directly impacts machine throughput, which typically has the largest impact on machine shop profitability.

The high-speed machining capabilities of brass rods maximize machine tool performance, allowing manufacturers to run the material faster and longer without sacrificing tool life, chip formation, or surface quality.

The high machining efficiency of brass leads to reduced per-part costs, quicker return on investment (ROI) for new machine tools, and expanded production capacity for new projects.

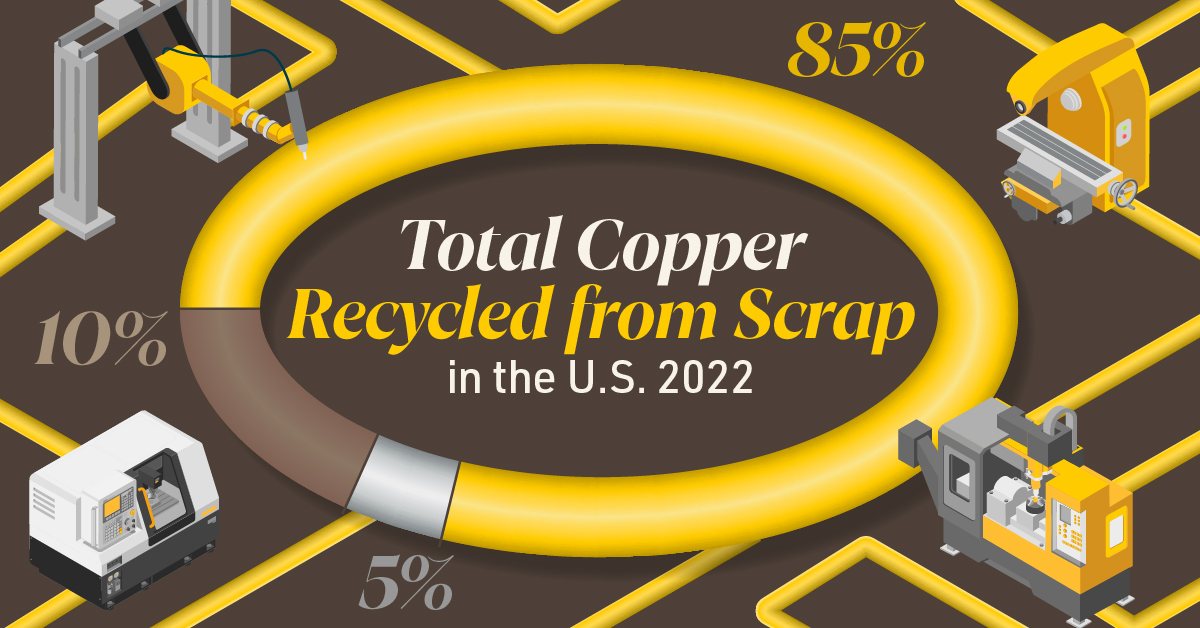

Supply Security Through Closed Loop Recycling

Brass, like its parent element copper, can be infinitely recycled.

In 2022, brass- and wire-rod mills accounted for the majority of the 830,000 tonnes of copper recycled from scrap in the U.S.

Given that scrap ratios for machined parts typically range from 60-70% by weight, producing mills benefit from a secure and steady supply of clean scrap returned directly from customers, which is recycled to create new brass rods.

The high residual value of brass scrap creates a strong recycling incentive. Scrap buy back programs give manufacturers greater control over raw material net costs as scrap value is often factored into supplier purchase agreements.

Next Generation Alloys for a Lead-Free Future

Increasingly stringent global regulations continue to pressure manufacturers to minimize the use of materials containing trace amounts of lead and other harmful impurities.

The latest generation of brass-rod alloys is engineered to meet the most demanding criteria for lead leaching in drinking water and other sensitive applications.

Seven brass-rod alloys passed rigorous testing to become the only ‘Acceptable Materials’ against lower lead leaching criteria recently adopted in the national U.S. drinking water quality standard, NSF 61.

Learn more about the advantages of brass rods solutions.

Misc

Brass Rods: The Safe Choice

From airbags to firefighting equipment, components made from brass rods play a vital role in creating a safer environment.

Brass Rods: The Safe Choice

From airbags to firefighting equipment, components made from brass rods play a vital role in creating a safer environment.

This infographic from the Copper Development Association illustrates three use cases for brass. This is the first of three infographics in our Choose Brass series.

Why Brass?

Brass is one of the most reliable metals for industrial and other applications. It contains little to no iron, protecting it from oxidation, which can cause other materials to fail over time.

Additionally, the malleability of brass ensures tight and leak-free metal-to-metal seals for threaded joints, minimizing the risk of costly and dangerous system failures. Brass’s durability ensures critical system components function properly for years.

Brass for Safe Water Systems

Exposure to lead in water can cause various health problems, including neurological damage, developmental delays, and cardiovascular diseases.

As a result, the U.S. sets minimum health-effect requirements for chemical contaminants and impurities indirectly transferred to drinking water from products, components, and materials used in water systems.

Currently, only brass rod alloys are designated as “acceptable materials” according to national standards.

Brass is also essential for ensuring workplace safety, particularly in high-risk manufacturing environments.

Using Brass for Safe Manufacturing and Industrial Environments

Brass is used extensively in industrial applications such as machinery components, valves, fittings, architectural elements, bearings, and gears.

The machinability of brass rods also means longer tool life and higher productivity for manufacturers of precision parts.

The microstructure of brass helps break up metal chips generated during machining operations, preventing long and stringy chips that can crash machines and seriously injure operators.

Additionally, brass’s non-sparking properties make it ideal for tooling, fittings, and components in high-risk industries such as oil & gas, chemicals, pharmaceuticals, paint manufacturing, power plants, and explosives.

Brass for Safer Communities

Many pieces of equipment in our daily lives also rely on brass rod parts to function. Control valves in gas stoves, BBQs, and home furnaces made from brass rods reduce the risk of deadly gas leaks and fires.

Moreover, brass is ideal for firefighting equipment due to its corrosion resistance, durability, heat resistance, and non-sparking properties.

Fittings made from brass rods ensure that the brakes and airbags in our vehicles work when needed.

Brass and other copper-based alloys are also naturally antimicrobial, helping prevent diseases when used in high-touch surfaces such as door handles.

These are only some of the ways that brass rods help build a safer world for everyone.

Explore the Advantages of Brass Rod Solutions.

-

Electrification3 years ago

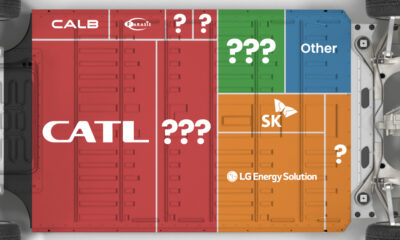

Electrification3 years agoRanked: The Top 10 EV Battery Manufacturers

-

Electrification2 years ago

Electrification2 years agoThe Key Minerals in an EV Battery

-

Real Assets3 years ago

Real Assets3 years agoThe World’s Top 10 Gold Mining Companies

-

Misc3 years ago

Misc3 years agoAll the Metals We Mined in One Visualization

-

Electrification3 years ago

Electrification3 years agoThe Biggest Mining Companies in the World in 2021

-

Energy Shift2 years ago

Energy Shift2 years agoWhat Are the Five Major Types of Renewable Energy?

-

Electrification2 years ago

Electrification2 years agoMapped: Solar Power by Country in 2021

-

Electrification2 years ago

Electrification2 years agoThe World’s Largest Nickel Mining Companies