Misc

What Are Birthstones?

View the full resolution version of this graphic.

What Are Birthstones?

Many cultures throughout history have revered gemstones.

Gemstones are minerals, rocks, or organic matter that have been chosen for their beauty, durability, and rarity, and then cut or faceted, and polished to make jewelry or other human adornments. There are over 300 gemstones currently documented.

A birthstone is a gemstone that represents a person’s period of birth—usually corresponding to the month or zodiac sign.

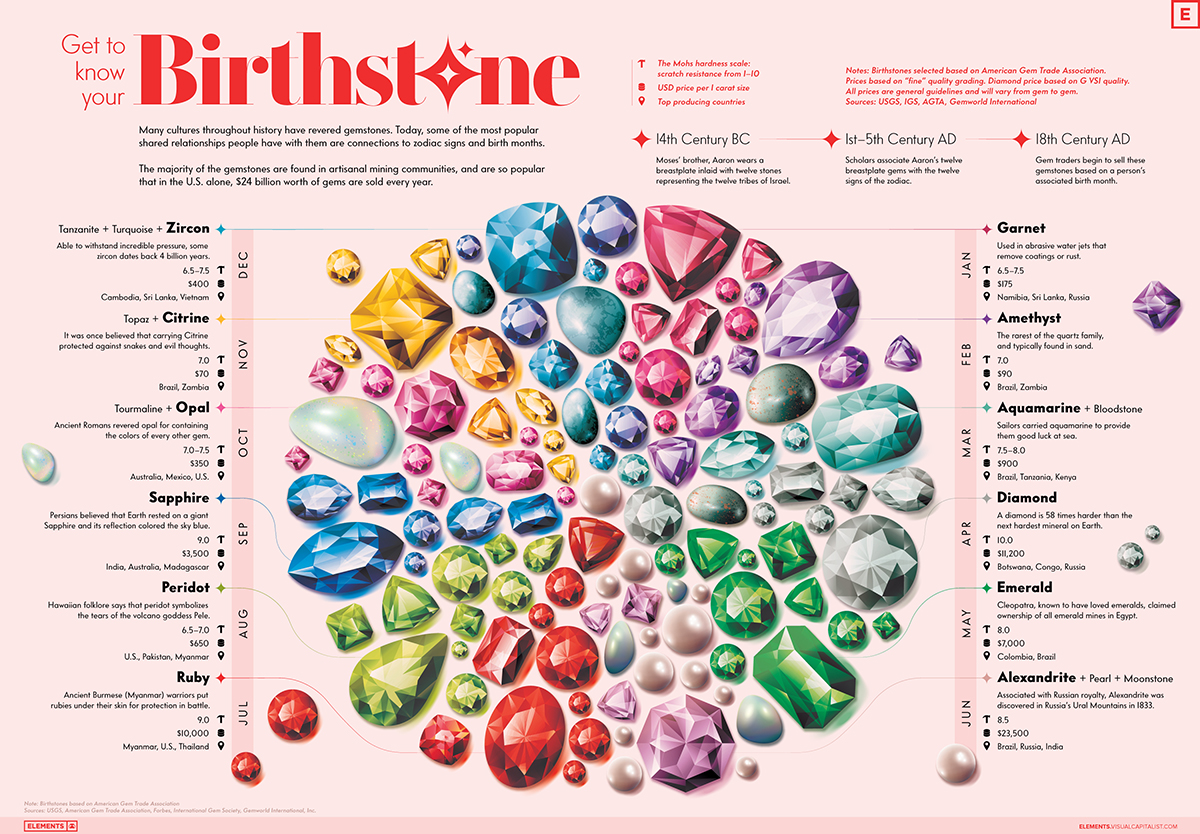

In this graphic based on data from the American Gem Trade Association, we look deep into 12 popular birthstones.

What do Birthstones Mean?

Different ancient cultures revered gemstones and connected them to their calendar systems, so there are different lists of birthstones and months that can have more than one gemstone. In Hinduism, for example, there are nine gemstones associated with the Navagraha (celestial forces including the planets, the Sun, and the Moon), known in Sanskrit as Navaratna (nine gems).

Another origin of birthstones traces back to the book of Exodus in the Bible. In Exodus 28, Moses sets forth directions for making special garments for Aaron, the Hebrews’ High Priest and Moses’ elder brother. Specifically, the breastplate was to contain 12 precious gemstones, representing the 12 tribes of Israel.

Given the historical age and numerous translations of the Bible through the ages, there’s been a lot of debate around the identification of the 12 gemstones and no agreement on what the gems actually were.

About 1,500 years after Aaron’s time, in the first centuries of the Christian era, scholars started associating the breastplate gems with the signs of the zodiac. During the 18th century AD, gem traders began to sell gemstones based on a person’s birth month.

| Birthstone | Birth Month | Hardness (1-10) | Price (USD per 1 carat size) | Producing Country |

|---|---|---|---|---|

| Garnet | January | 6.5-7.5 | $175 | Namibia, Sri Lanka, Russia |

| Amethyst | February | 7.0 | $90 | Brazil, Zambia |

| Aquamarine | March | 7.5-8.0 | $900 | Brazil, Tanzania, Kenya |

| Diamond | April | 10.0 | $11,200 | Botswana, Congo, Russia |

| Emerald | May | 8.0 | $7,000 | Colombia, Brazil |

| Alexandrite | June | 8.5 | $23,500 | Brazil, Russia, India |

| Ruby | July | 9.0 | $10,000 | Myanmar, U.S., Thailand |

| Peridot | August | 6.5-7.0 | $650 | U.S., Pakistan, Myanmar |

| Sapphire | September | 9.0 | $3,500 | India, Australia, Madagascar |

| Opal | October | 7.0-7.5 | $350 | Australia, Mexico, U.S. |

| Citrine | November | 7.0 | $70 | Brazil, Zambia |

| Zircon | December | 6.5-7.5 | $400 | Cambodia, Sri Lanka, Vietnam |

In some cultures, it is generally agreed that wearing a gemstone during the month when it is the birthstone heightens its healing powers.

The Birthstones Market

The majority of colored gemstones are extracted by artisanal mining communities around the world, in a very decentralized market.

Gemstone prices can vary from $68 per carat for citrine (November) up to $23,500 per carat for Alexandrite (June). The United States is the leading global market, buying roughly $24 billion in gemstones per year.

Besides different colors and prices, birthstones are also measured according to their hardness. The hardness is evaluated using a scale of 1-10 created by Friedrich Mohs that considers the ability to resist scratching. Diamonds (April) rank 10, being 58 times harder than any other mineral on Earth.

To this day, jewelers continue to add options to birthstone lists. Citrine and spinel (August), for example, are modern additions. Likewise, Tanzanite (December)—the second fastest-selling colored gemstone after Sapphire (September)—was only discovered in 1967 by herders in Tanzania.

Misc

Brass Rods: The Secure Choice

This graphic shows why brass rods are the secure choice for precision-machined and forged parts.

Brass Rods: The Secure Choice

The unique combination of machinability and recyclability makes brass rods the secure choice for manufacturers seeking future-proof raw material solutions.

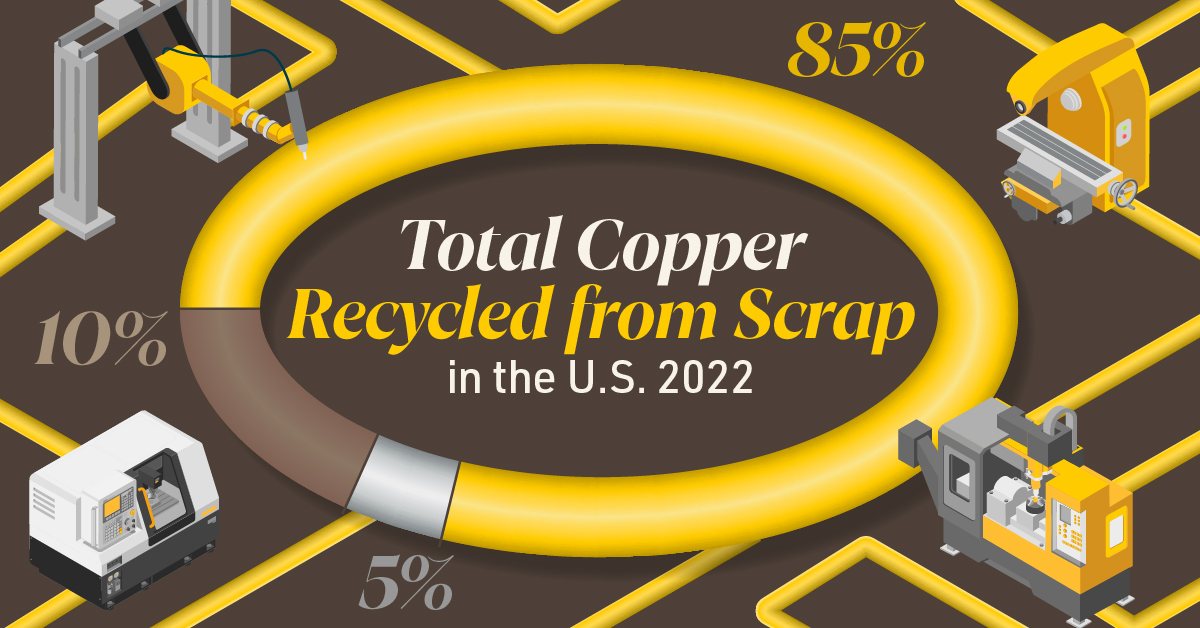

This infographic, from the Copper Development Association, shows three ways brass rods give manufacturers greater control and a license to grow in the competitive market for precision-machined and forged products.

Future-Proof Investments in New Machine Tools

A material’s machinability directly impacts machine throughput, which typically has the largest impact on machine shop profitability.

The high-speed machining capabilities of brass rods maximize machine tool performance, allowing manufacturers to run the material faster and longer without sacrificing tool life, chip formation, or surface quality.

The high machining efficiency of brass leads to reduced per-part costs, quicker return on investment (ROI) for new machine tools, and expanded production capacity for new projects.

Supply Security Through Closed Loop Recycling

Brass, like its parent element copper, can be infinitely recycled.

In 2022, brass- and wire-rod mills accounted for the majority of the 830,000 tonnes of copper recycled from scrap in the U.S.

Given that scrap ratios for machined parts typically range from 60-70% by weight, producing mills benefit from a secure and steady supply of clean scrap returned directly from customers, which is recycled to create new brass rods.

The high residual value of brass scrap creates a strong recycling incentive. Scrap buy back programs give manufacturers greater control over raw material net costs as scrap value is often factored into supplier purchase agreements.

Next Generation Alloys for a Lead-Free Future

Increasingly stringent global regulations continue to pressure manufacturers to minimize the use of materials containing trace amounts of lead and other harmful impurities.

The latest generation of brass-rod alloys is engineered to meet the most demanding criteria for lead leaching in drinking water and other sensitive applications.

Seven brass-rod alloys passed rigorous testing to become the only ‘Acceptable Materials’ against lower lead leaching criteria recently adopted in the national U.S. drinking water quality standard, NSF 61.

Learn more about the advantages of brass rods solutions.

Misc

Brass Rods: The Safe Choice

From airbags to firefighting equipment, components made from brass rods play a vital role in creating a safer environment.

Brass Rods: The Safe Choice

From airbags to firefighting equipment, components made from brass rods play a vital role in creating a safer environment.

This infographic from the Copper Development Association illustrates three use cases for brass. This is the first of three infographics in our Choose Brass series.

Why Brass?

Brass is one of the most reliable metals for industrial and other applications. It contains little to no iron, protecting it from oxidation, which can cause other materials to fail over time.

Additionally, the malleability of brass ensures tight and leak-free metal-to-metal seals for threaded joints, minimizing the risk of costly and dangerous system failures. Brass’s durability ensures critical system components function properly for years.

Brass for Safe Water Systems

Exposure to lead in water can cause various health problems, including neurological damage, developmental delays, and cardiovascular diseases.

As a result, the U.S. sets minimum health-effect requirements for chemical contaminants and impurities indirectly transferred to drinking water from products, components, and materials used in water systems.

Currently, only brass rod alloys are designated as “acceptable materials” according to national standards.

Brass is also essential for ensuring workplace safety, particularly in high-risk manufacturing environments.

Using Brass for Safe Manufacturing and Industrial Environments

Brass is used extensively in industrial applications such as machinery components, valves, fittings, architectural elements, bearings, and gears.

The machinability of brass rods also means longer tool life and higher productivity for manufacturers of precision parts.

The microstructure of brass helps break up metal chips generated during machining operations, preventing long and stringy chips that can crash machines and seriously injure operators.

Additionally, brass’s non-sparking properties make it ideal for tooling, fittings, and components in high-risk industries such as oil & gas, chemicals, pharmaceuticals, paint manufacturing, power plants, and explosives.

Brass for Safer Communities

Many pieces of equipment in our daily lives also rely on brass rod parts to function. Control valves in gas stoves, BBQs, and home furnaces made from brass rods reduce the risk of deadly gas leaks and fires.

Moreover, brass is ideal for firefighting equipment due to its corrosion resistance, durability, heat resistance, and non-sparking properties.

Fittings made from brass rods ensure that the brakes and airbags in our vehicles work when needed.

Brass and other copper-based alloys are also naturally antimicrobial, helping prevent diseases when used in high-touch surfaces such as door handles.

These are only some of the ways that brass rods help build a safer world for everyone.

Explore the Advantages of Brass Rod Solutions.

-

Electrification3 years ago

Electrification3 years agoRanked: The Top 10 EV Battery Manufacturers

-

Electrification2 years ago

Electrification2 years agoThe Key Minerals in an EV Battery

-

Real Assets3 years ago

Real Assets3 years agoThe World’s Top 10 Gold Mining Companies

-

Misc3 years ago

Misc3 years agoAll the Metals We Mined in One Visualization

-

Electrification3 years ago

Electrification3 years agoThe Biggest Mining Companies in the World in 2021

-

Energy Shift2 years ago

Energy Shift2 years agoWhat Are the Five Major Types of Renewable Energy?

-

Electrification2 years ago

Electrification2 years agoThe World’s Largest Nickel Mining Companies

-

Electrification2 years ago

Electrification2 years agoMapped: Solar Power by Country in 2021